CGI

Executive summary

The challenge: LVMH’s strategy teams were running global stock predictions on a fragile house of cards—manual CSV exports and disjointed spreadsheets. The process was slow, prone to human error, and threatened data integrity for brands like Dom Pérignon.

The constraints: We were building on SAP HANA a powerful backend with a notoriously rigid frontend. I had to act as a hybrid designer-developer to bend the platform’s limitations without breaking the database.

The outcome: Reduced a multi-day stock estimation process to 3 hours:

- Reduced estimation cycle time by ~90% (from 3 days to 3 hours).

- Eliminated 100% of file corruption errors by removing manual CSV handling.

- Unlocked real-time scenario modeling for the first time in the department’s history.

The invisible logistics of luxury

When we think of Dom Pérignon or Moët & Chandon, we think of the bottle, not the spreadsheet. But for the business strategy teams at LVMH, the reality was a fragile ecosystem of manual CSV exports and disjointed tools.

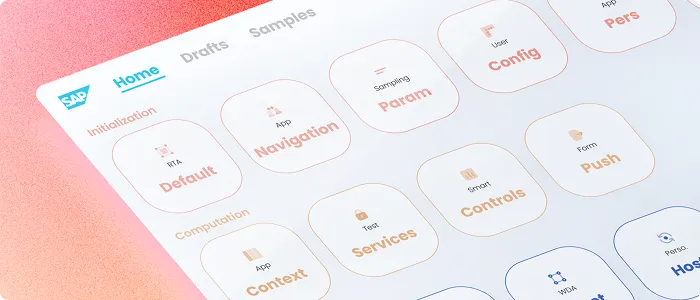

I was brought in to dismantle this legacy process and rebuild it from the ground up as a custom web application suite on SAP HANA. The mandate wasn’t just migration; it was to recreate the entire workflow, improve data reliability, and ship new forecasting features that expert users didn’t even know they could have.

The spreadsheet dependency

The existing workflow was a house of cards. To estimate champagne unit demand, users had to swap between various tools, constantly exporting and importing data. The friction wasn’t just annoyance; it was a business risk. File corruption and metric conversion failures were common. A single human error during a file transfer could skew stock predictions for a global brand. We needed to create a system that maintained data integrity while allowing users to manipulate variables freely.

Designing against the grain

The primary constraint was the technology. SAP HANA is a powerhouse for data processing, but it is notoriously rigid regarding front-end customization. Standard SAP interfaces are often cluttered and counter-intuitive.

Most designers hit a wall here, accepting “SAP can’t do that” as an answer. To push back, I had to learn the medium. I spent weeks reading SAP documentation to understand the technical parameters of the environment. This wasn’t about coding for the sake of it; it was about bridging the gap between design intent and technical feasibility. I needed to know exactly how far we could bend the framework before it broke.

Recreating the workflow (and shipping new value)

We focused on two main strategic shifts to improve the system: Modular linearity: We broke the monolithic spreadsheet process into a collection of specific tools (Financial, Stock, Context) that processed input from previous stages automatically. We shipped new features that allowed for real-time scenario modeling—something impossible in their old CSV workflow. The emergency exit: Legacy ERP systems often trap users in a process. If you make a mistake, you have to start over. Leveraging Nielsen’s heuristics, we engineered “emergency exits” into the flows, allowing users to undo actions or back out of a process without data loss. This gave users the confidence to explore scenarios without fear of breaking the database.

The outcome

By moving from a disjointed file system to an organic collection of apps, we drastically reduced the time required for stock strategy cycles. A task that previously consumed several working days could now be completed in a matter of hours.

More importantly, we didn’t just make it faster; we made it smarter. The new environment allowed LVMH strategists to manage stock with a level of flexibility and reliability they had never experienced before. My biggest takeaway wasn’t just the interface design, but the value of technical empathy, learning the developer’s constraints allowed me to design a solution that was actually shippable, rather than just a pretty mockup that died in development.